What are the cooling methods for Hot-rolled steel plates?

- Time:2025-11-24 15:29:45

- Hits:160

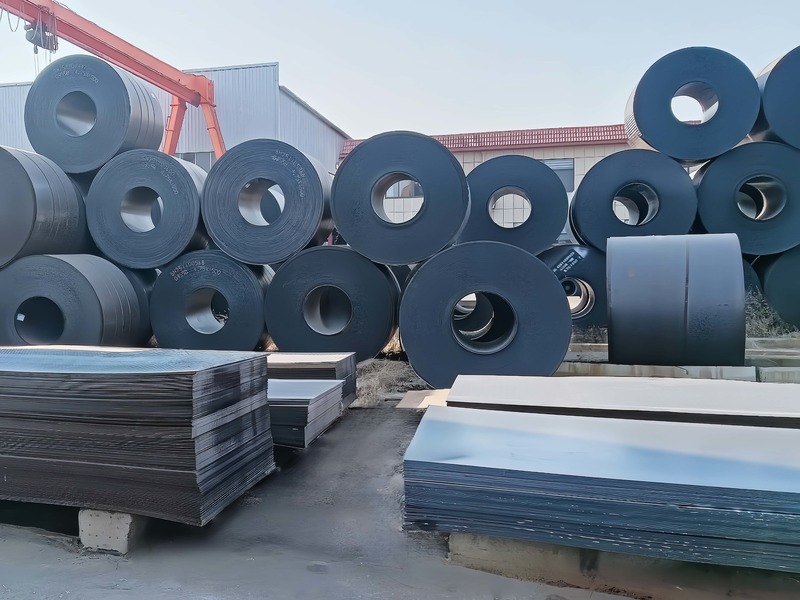

The core cooling methods for Hot-rolled steel platesare divided into two categories: natural cooling and forced cooling, which are suitable for different product types (medium thick plates, coils) and performance requirements. The brief classification and characteristics are as follows:

1、 Natural cooling (passive cooling)

Air cooling (stack cooling)

Method: After hot rolling, the steel plate is directly placed in the air or naturally dissipated after stacking

Applicable: Medium thick plates, ordinary carbon structural steel (such as Q235), products with low precision requirements

Features: Simple process, low cost, slow cooling rate (5-15 ℃/min), uniform grain size, good toughness, but low efficiency and easy oxidation

Pit cooling/slow cooling Pit cooling

Method: Place the hot-rolled plate into the insulation pit, cover it with an insulation cover, and slowly cool it down

Applicable: High carbon steel plate, alloy steel plate, thick specification medium thick plate (>50mm)

Features: Extremely slow cooling rate (1-5 ℃/min), reduces internal stress, avoids cracks, and improves processing performance

2、 Forced cooling (active cooling)

Laminar cooling (mainstream method)

Method: High pressure layer water mist/water flow vertically sprayed onto the surface of the steel plate (divided into upper and lower headers), precise control of cooling speed

Applicable: Hot rolled coils, thin specification medium thick plates (≤ 20mm), high-strength steels (such as Q355, Q460)

Features: Fast cooling speed (20-100 ℃/min), adjustable grain size, improved strength and toughness, high efficiency, making it the core cooling process for rolled plates

Spray cooling

Method: High pressure atomizing nozzle sprays water mist, balancing cooling efficiency and uniformity

Applicable: Cooling after finishing of medium and thick plates, special steel grades (such as weather resistant steel)

Features: Medium cooling rate (15-30 ℃/min), avoiding water marks or cracks on the surface of the steel plate

Water cooling (online rapid cooling)

Method: The steel plate is passed through a closed water tank, and high-pressure water flows quickly to wash the surface

Applicable: Thin specification hot-rolled plate (≤ 6mm), high-strength strip steel

Features: Extremely fast cooling speed (100-200 ℃/min), significantly improving steel strength and shortening production cycle

forced air cooling

Method: High power fan blows cold air to forcefully dissipate heat from the surface of the steel plate

Applicable: Steel plates with high surface quality requirements (avoiding watermarks), thin specification medium thick plates

Features: Moderate cooling rate (10-25 ℃/min), no residual moisture on the surface, and reduced peeling of oxide skin