The process flow of Hot-rolled Steel Plates?

- Time:2025-11-24 15:27:48

- Hits:135

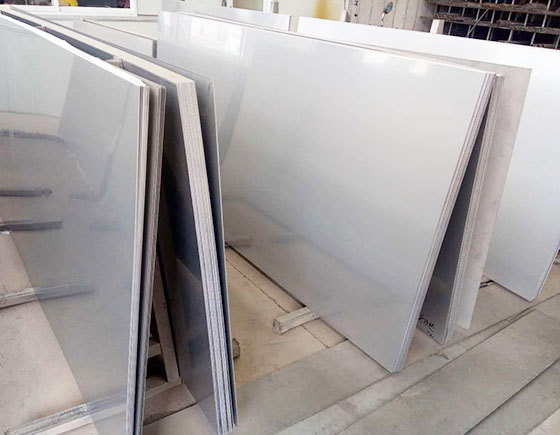

The core production process of hot-rolled plates (including medium thick plates and hot-rolled coils) is as follows:

Raw material preparation: Select continuous casting slab (thickness 100-300mm), surface cleaning (flame/grinding wheel to remove oxide scale and defects)

Heating: Use a step heating furnace to heat up to 1150-1300 ℃ and hold for 2-4 hours (to ensure uniform heat transfer of the steel billet)

Scale removal: Rinse the surface oxide layer with high-pressure water (15-25MPa) to avoid defects caused by pressing into the steel plate

Rolling:

Rough rolling: Multi pass widening+thickness reduction (reversible rolling mill for medium and thick plates, hot rolling mill for coils)

Precision rolling: Control the final rolling temperature (850-950 ℃), fixed thickness (1.5-200mm)+shape control

Cooling:

Medium thick plate: natural cooling/stack cooling; Roll plate: laminar cooling (control cooling rate to ensure mechanical properties)

Finishing:

Medium thick plate: straightening → trimming and sizing → surface cleaning

Roll board: Roll up → flatten → divide into rolls → cut head and tail

Packaging inspection: size/appearance inspection → mechanical performance sampling → labeling and bundling before leaving the factory