What are the differences between hot-rolled galvanized steel sheets and cold-rol

- Time:2025-11-24 14:40:38

- Hits:145

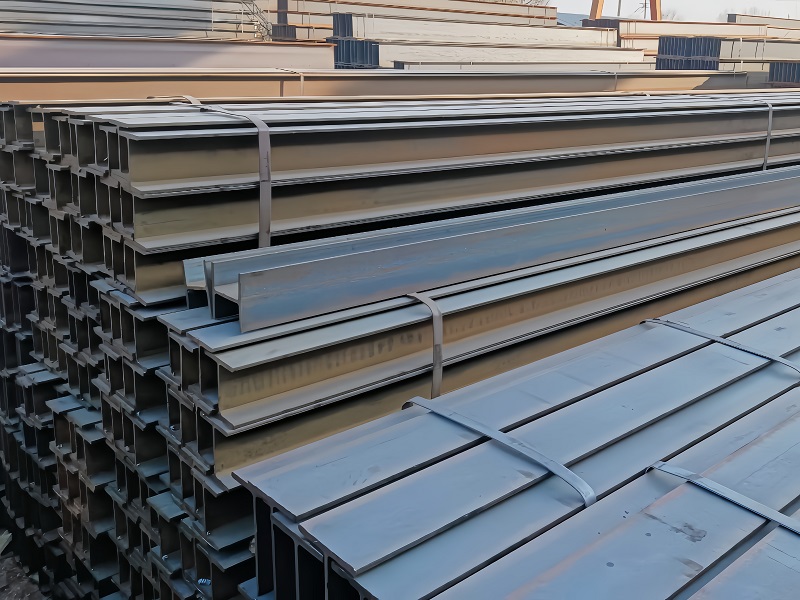

Because hot-rolled substrates have one less process than cold-rolled substrates, galvanizing hot-rolled substrates has lower production costs than cold-rolled substrates, mainly due to annealing costs and cold-rolled rolling costs, while the other processes are similar. Hot rolled substrates have a relatively rough surface due to only acid washing and annealing to remove surface impurities. The zinc layer has good adhesion, and the coating thickness tends to be around 140/140g/m2. But the thickness dimension is not as precise as cold rolling, and due to the fact that most of them are thick zinc layers, the thickness control of the zinc layer is also uneven. There is not much difference in mechanical properties, and some properties are even better than cold rolling. Hot rolled galvanized sheet is commonly used for structural components with low surface requirements but high strength and thickness requirements, as its dimensional accuracy and surface quality are not as good as cold-rolled galvanized sheet, and its thickness is thicker than cold-rolled galvanized sheet.

Because hot-rolled galvanized sheet has low cost, and with the progress of technology, the specification thickness is also increasing, and the usage is gradually increasing. The main raw materials for ironmaking, iron ore, coke, and coal, are transformed into molten iron through a series of reactions in the blast furnace. The molten iron and scrap steel are processed into molten steel through a converter. Molten steel can be processed into slabs through continuous casting, or into steel ingots through mold casting and finally processed into slabs, square billets, and tube billets in the primary rolling plant. Due to the avoidance of the mold casting process in continuous casting, the composition of steel is more uniform, and the yield and quality of finished products are greatly improved. Steel ingots, slabs, initial rolled billets, and tube billets are semi-finished products. Except for a small portion that is directly sold to the market, most of them will be made into finished products through the next rolling process. Slabs, billets, and billets are raw materials used to produce hot-rolled products, steel wires, steel bars, and pipes, respectively. They are ultimately used to produce hot-rolled coils, wires, and seamless steel pipes of different grades and applications.

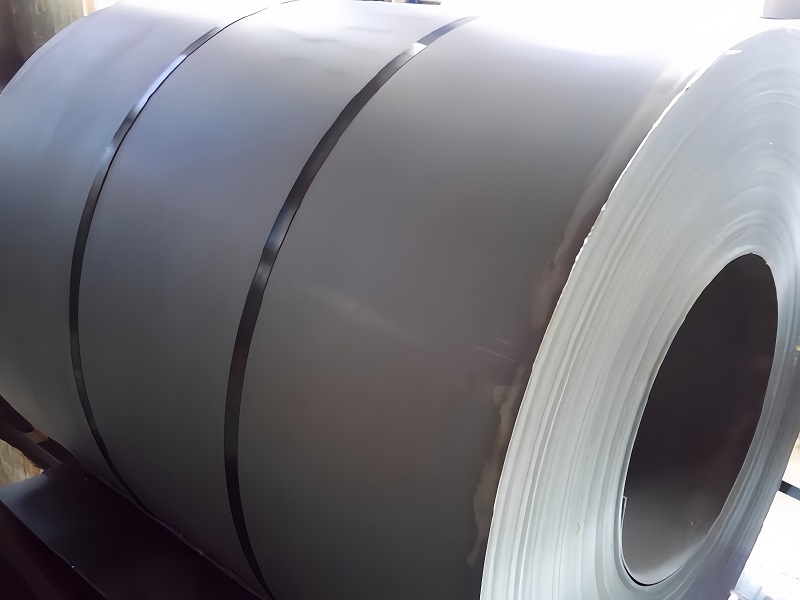

Hot rolled coils are sold as finished products; Part of it is used as raw material for cold rolling, which undergoes acid washing, rolling, annealing, coating, and painting to produce high value-added cold-rolled coils, including electroplated galvanized coils, hot-dip galvanized coils, and color coated coils. Cold and hot rolled steel plates are degreased by alkali washing, washed with water, dried, and then annealed in a horizontal (vertical) heating furnace with radiation tubes. A certain amount of hydrogen gas is introduced into the furnace to create a reducing atmosphere. The steel strip heated to a certain temperature is immersed in zinc solution under certain conditions for hot-dip galvanizing. After the strip steel immersed in galvanizing comes out of the zinc pot, the amount of galvanizing is controlled by an air knife, and the size of the flower is controlled by the composition of the liquid zinc. At the same time, a forced cooling method is used to control it. Before the zinc flower begins to spread, the small zinc flower product is cooled using a small zinc flower equipment to prevent the zinc liquid from continuing to spread and form small zinc flowers. After being hot-dip galvanized, the steel strip is cooled and polished on the surface, and then subjected to surface passivation treatment or directly produced into color coated coils according to its purpose.